Gas loading and unloading processes are critical for the feasibility of the GASVESSEL concept. GASVESSEL partner CENERGY is developing a multiscale simulation model for these processes that are used for the system design of the GASVESSEL.

Loading and unloading processes are critical for the feasibility of the GASVESSEL concept since they affect in a critical manner the time for gas loading and unloading, the amount of energy required for the loading and the unloading processes, and the overall cost of the loading and unloading plant. During 2018 CENERGY started the development of a multiscale simulation model of the loading and unloading processes that has been used to support the system design phase based on the operational conditions. The simulation model will be used in the cylinder operation of the GASVESSEL as well as to define the best sequence in the loading and unloading processes of the pressure vessel, optimizing both duration and energy consumption. The simulation model is parametric and therefore allows to compare a variety of solutions in terms of system components.

The loading and unloading plant includes:

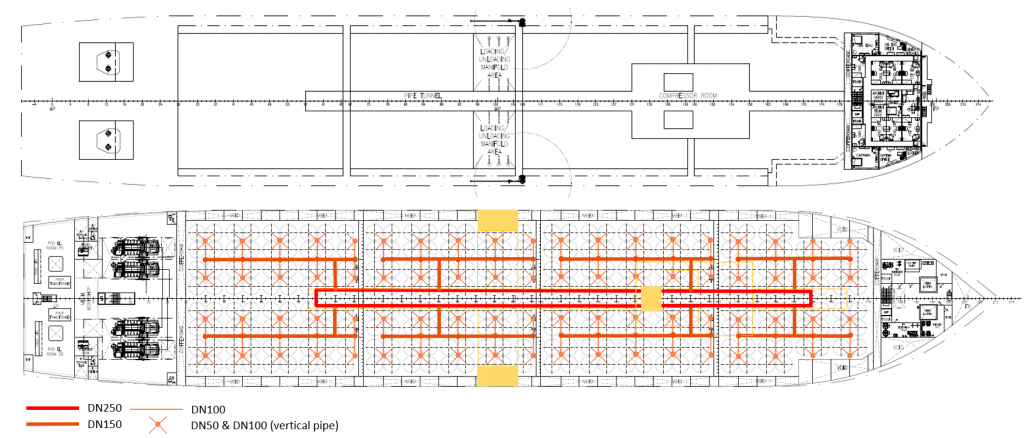

- piping of different diameter (see Figure)

- control valves

- the compressor

- heat exchangers

- the pressure vessels

Fig. 1: Schematic of the piping layout of the GASVESSEL

Loading process

The loading process is divided into two different phases:

- Free Loading (without use of the compressor)

- Forced Loading (with the use of the centrifugal compressor)

The loading process starts with a pressure inside the pressure vessels of 30 bar and the process ends when the pressure reaches 300 bar. The filling system consists of a storage terminal loaded at 240 bar. Two different possibilities for loading have been preliminary investigated: filling with constant temperature and pressure (the storage terminal is considered as an infinite tank) and filling from a storage terminal with a double volume compared to the total GASVESSEL volume.

Unloading process

The unloading process is again divided into two phases:

- Free Unloading in the gas pipeline (the pipeline pressure is at 120 bar);

- Forced Unloading with the use of the same centrifugal compressor of the loading process – at the end of this phase the pressure inside the pressure vessels reaches 30 bar.

Dynamic model

The dynamic model for the pressure vessels is based on the following four fundamental equations:

- Mass Conservation

- Energy Balance

- Orifice Flow Equation

- Heat exchange through the pressure vessels wall

So far, this model has been used to estimate the energy required for the loading process and the energy required during the unloading process. Moreover, the model has been used to estimate the gas cooling needs during the loading process, in order not the overheat the pressure vessels. Additionally, also the maximum allowable discharge rate during the unloading process has been estimated, in order not to undercool the pressure vessels and therefore approach conditions that could be detrimental to the mechanical resistance of the pressure vessels, piping and valves.

During 2019 the model will be further verified and optimized to be used during all operational phases of GASVESSEL.