During the last months, ABS Hellenic has been actively working on the safety assessments and systems for the Cargo gas containment within WP8. One of the objectives of the WP8 Class design review – safety assessments is to carry out a risk assessments and studies required by the Class Rules for the GASVESSEL CNG carrier design and operations.

HAZOP workshop

The leader of the WP8 ABS Hellenic is coordinating all consortium efforts and oversee the respective tasks taken towards this objective in WP8. Therefore, ABS Consulting has organized a Hazard Operability (HAZOP) workshop in the first quarter of 2021. The main goal of the event was to identify the risks associated with the operation of CNG Ship and ensure they are adequately evaluated and mitigated.

Due to the COVID-19, the workshop was organized online on 22-24 February 2021. The 3-day event included organisations from various discipline within the project consortium. Main participants were the key contributors in the ship design development, operation and maintenance of the system Navalprogetti, CEnergy, Esteco and ABS.

Workshop objectives

During the workshop, the partners performed a study with accordance of the requirements set in ABS Guide for Vessels Intended to Carry Compressed Natural Gases. The objective of the assessment workshop was to:

- Identify hazards associated with the design and operations of the CNG transportation vessel operation.

- Develop hazard scenarios based on the deviations from the intended design/operation.

- Identify potential causes and consequence of interest associated with each deviation.

- Identify existing safeguards.

- Identify risk reduction measures if the existing safeguards are not deemed adequate.

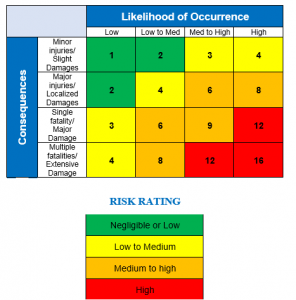

The consortium was heavily invested in analysing the safety and environmental consequences, as described in the predefined risk matrix.

The HAZOP approach

The HAZOP technique is a systematic method for identifying malfunctioning or improperly operating errors in the process equipment that could lead to undesirable conditions. The key elements of the HAZOP technique are defined by the following terms:

| Intentions | — | Successful operating states for process systems |

| Deviations | — | Departures from the design intentions |

| Causes | — | Reasons why the deviation might occur |

| Consequences | — | Potential effects of the deviations |

| Safeguards | — | Features designed to prevent the causes or mitigate the consequences of deviations |

| Recommendations | — | Suggestions for design changes, procedural changes, or further study |

To apply the HAZOP technique, the consortium divided the system into logical HAZOP “study nodes”, process sections, or operating steps. One at a time, the Hazop team examines a study node using a set of established “guide words” to identify potentially hazardous process deviations. For example, major vessels, interconnecting process piping, etc.

Firstly, the partners reviewed the piping and instrumentation diagrams (P&IDs), other appropriate process safety information. In addition, they also checked the equipment itself to help them identify hazards associated with deviations from the design intentions. Secondly, for each deviation, the consortium members applied the following approach.

- Decided whether consequences of interest would result from credible causes of deviations.

- Identified engineering and administrative safeguards protecting against particular deviations.

- Qualitatively evaluated risk associated with the deviations, and, if necessary,

- Made recommendations that might reduce the likelihood of the deviations or the severity of the consequences.

The results

Based on the insight gained from performing this hazard analysis, the consortium has come with 26 recommendations for reducing the risk of hazardous scenarios in compressed natural gas transport system

One of the key recommendations was to improve the “special studies” relevant to fire hazard and explosion. The partner Esteco has prepared this additional study that is referred to a jet fire in the compressor room. The report has been submitted to ABS.

All the recommendations will need to be incorporated into the design at the current or next design phase. The partners will meet once again to assess the new actions that needs to be taken under the scope of the Basic design Approval.