HAZID workshop team included participant from various discipline. This team included personnel from Navalprogetti S.r.l., ESTECO, Cenergy, and ABS, who were familiar with the intended design, operation, and maintenance of the system. In addition, the team included personnel from ABS AS, an engineering firm that specializes in process safety and reliability analysis. Per our agreement, ABS AS provided the risk engineer to facilitate the meetings, document the HAZID analysis, and provide knowledge of the hazard evaluation techniques used.

As part of its HORIZON 2020 initiative European Commission formed a consortium to develop a CNG transportation vessel for gas delivery on medium-short leg routes where offshore pipelines or LNG Ships are un-economic or impracticable.

The ship will receive the natural gas previously dehydrated and desulfurized by the production facility or CNG FSU. No provision on board the Ship is provided for preliminary treatments of the natural gas. The production facility or CNG FSU will supply the gas to the ship at abt. 240 bar. The ship is fitted with cargo compressors and relevant systems as necessary to rise the pressure from 240 to 300 bar inside the cylinders to increase the cargo carrying capacity.

Typical ship’s machinery, systems and components designed, constructed, supplied and installed to the manufacturer and/or Builder standard in compliance with the requirements of the ABS CNG guide and other regulatory bodies, as applicable. The ship power generation will be performed by four (4) dual fuel engines type Wartsila 8V31DF (4240 kW at 720 RPM each).

To ensure the hazards associated with the operation of vessel is adequately identified and mitigated, a Hazard Identification (HAZID) workshop was conducted from 27th February to 28th February 2019.

This study was performed in accordance with the requirements set forth in ABS Guide for Vessels Intended to Carry Compressed Natural Gases in Bulk/Section 2.

Scope

The objective of the assessment was to:

- Identify hazards associated with the design and operations of the CNG transportation vessel operation.

- Develop hazard scenarios and identify potential causes, assess the related consequences, and identify the existing protection, detection, and indicating mechanisms.

Suggesting opportunities of alternative options towards an inherently safer design or identify risk mitigation measures to reduce the estimated risk.

The Hazard Identification (HAZID) study is a systematic review of the possible causes and consequences of hazardous events. It can be applied to all or part of the vessel or it can be applied to analyze the operational procedures. It can be used for identification and assessment of potential hazards and their causes and consequences

Methodology

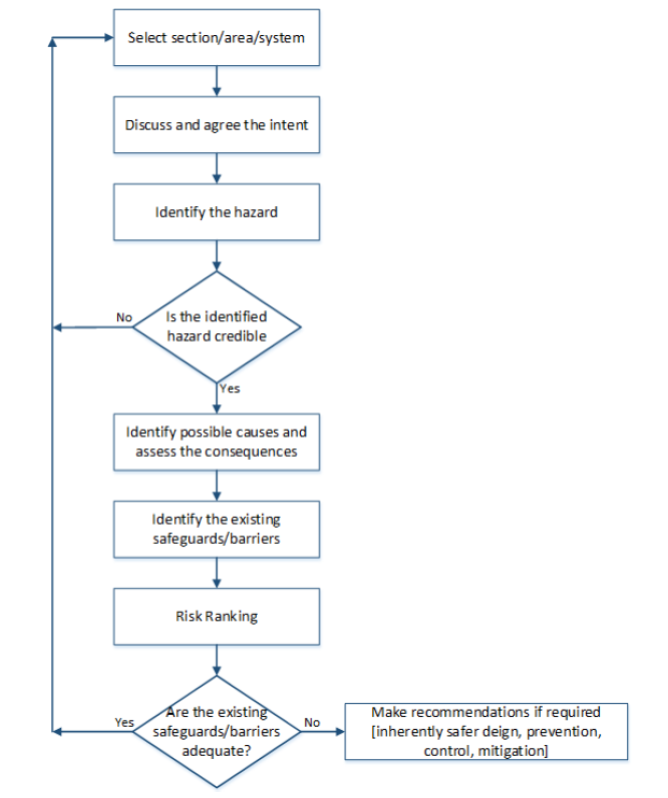

The basic HAZID study involves following tasks:

- The assembly of an appropriate team of experienced personnel, including representatives of all disciplines involved in the area being reviewed and (as needed) interfaces with adjacent systems.

- Completion of the HAZID workshop, the methodology of which is detailed in Figure 1

Figure 1: The HAZID Study Process

During the HAZID workshop, the following activities were performed:

- Application of the relevant guidewords to identify hazards and other HSE concerns.

- Use the list of HAZID guidewords provided and if required identify any further guidewords (or Issues of Concern) that require coverage or consideration;

- Brainstorm to identify all potential causes that could result in a “hazard scenario” developing related to that guideword/Issue of concern;

- Identify the worst credible consequence associated with realization of the hazard scenario; for this study primary focus will be on scenarios that can lead to safety and environmental consequences.

- Identify the safeguards and controls in place to help to prevent the scenario from starting and those that mitigate the ultimate consequences should it occur;

- Perform a risk ranking for each of the identified scenarios;

- Use the risk ranking to help to assess whether the current controls and safeguards are considered adequate, if not then look to identify additional safeguards/controls to help reduce the risk (or identify areas where further review or analysis is required to better understand the risk and potential mitigating measures) and record these as Actions;

- Repeat for all review areas until complete scope of the HAZID has been studied.

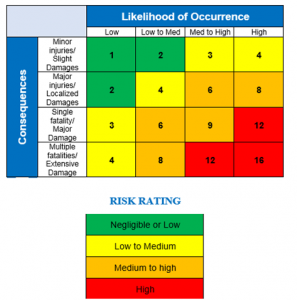

- Risk ranking was performed as per the risk matrix provided in Table 1

- HAZID workshop was recorded in the worksheet template as provided in Table 2.

Table 1 Risk Matrix & Table 2 Worksheet Template

The physical scope of the HAZID included the design and operations of the vessel, and loading/unloading operations. To perform the thorough review of the design and its associated effect on the vessel operation, the design was divided into nodes as following:

- Cargo containment system (cylinders)

- Cargo loading and unloading header and fuel gas piping arrangement

- Compressor room and fuel gas system

- Gas combustion unit

- Nitrogen system

- Main engine and engine room

- Ship interface and marine systems

Following operating modes/scenario will be considered for each of the above nodes, where applicable:

- Inerting

- Loading

- Depressurization

- Cool down

- Filling

- Normal operation

- Startup/shutdown

- Dry dock

- Emergency shutdown

- Extended shutdown

Guide words were selected to stimulate discussion within a node and identify hazard scenarios that articulate how the hazard is realized and the potential consequence that might arise.

Assumptions

In order for a successful HAZID to be conducted there are some key assumptions that were made during the workshop:

- Gas detection will be provided in areas where gas may accumulate

- Ventilation fans that may handle gas vapors are to be of the non-sparking type.

- No gas containing piping will be routed through an accommodation or service spaces.

- Vessel is designed and constructed according to all applicable standards and regulations. HAZID scope does not include the review of codes and standard against design in consideration.

- Onshore loading systems and equipment were not part of the HAZID scope

Results

Based on the review and insight gained from performing this HAZID analysis, the HAZID team made 27 recommendations, as listed in the Hazard Register for the design. A system shall be established to address the HAZID analysis team’s recommendations and ensure that the recommendations are incorporated into the design or otherwise resolved early in the next design phase. It is anticipated that additional hazards may be identified as more details are available during further development of the project phases and accordingly this register should be kept up to date, with items closed out and added, as appropriate